The Effects of 3D Printing on the Supply Chain

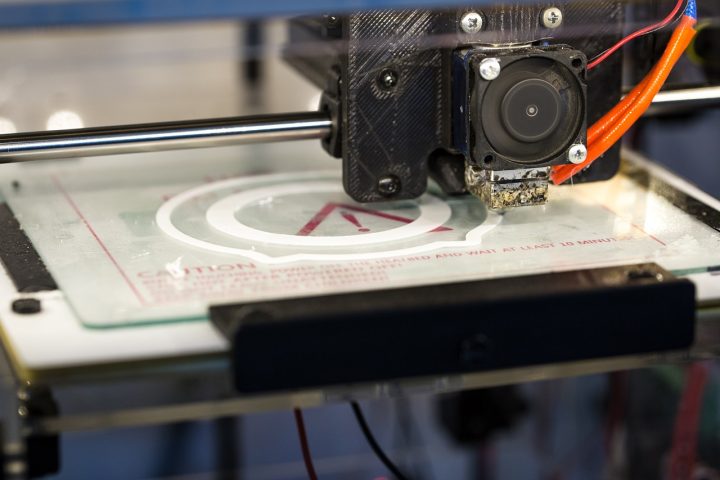

3D printing is among the most intriguing disruptors to production. The ability to print anything with a blueprint from nearly any material is fascinating, particularly for businesses in niche industries that require specific parts.

While 3D printing isn’t currently revolutionizing supply chains, the potential is incredible. Some businesses have already found viable uses for the technology in their current supply chain, too.

Your supply chain may not currently be utilizing 3D printers, but 3D printers could soon shorten the supply chain process and make your logistics more efficient than ever.

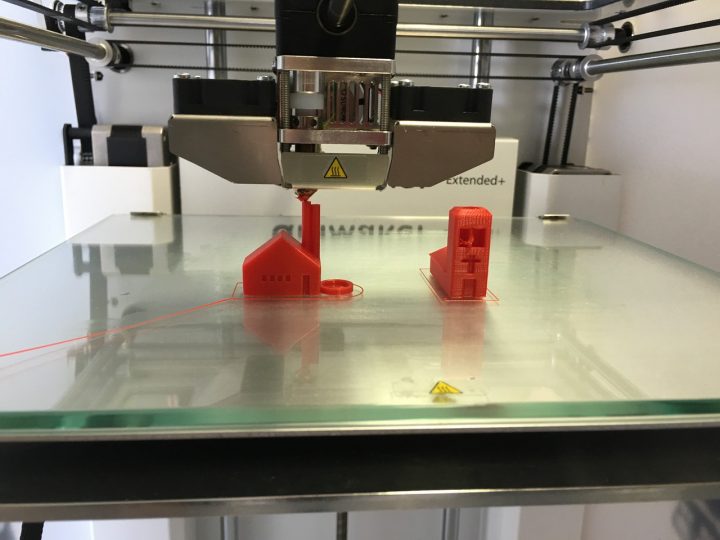

The technology behind 3D printing, also known as additive manufacturing, is likely older than you were expecting. Starting in the 1980s, businesses were already experimenting with ways to print 3D objects. Using methods such as stereolithography (SL), the businesses could “print” objects by firing a laser into a liquid or powder, making complex forms take shape.

Since its inception, additive manufacturing has been able to produce nearly any physical object — including a printer which can print other 3D printers.

While additive manufactured goods can be much more complex than mass-produced items, the 3D printing process is much slower and often more expensive, since a printer and raw materials are required. However, this hasn’t stopped logisticians from finding ways to implement 3D printers into supply chains.

The effect that 3D printing could have on your supply chain depends entirely on your industry. A large business that owns every part of the supply chain (manufacturing, warehousing, shipping, assembly, and production) could easily save time and cut steps with additive manufacturing.

However, an e-commerce business that only owns a website may not have an interest in paying a high premium for bespoke, 3D printed objects.

But additive manufacturing can save supply chains money and time in several different ways, and as 3D printing becomes more common and less expensive, you should expect 3D printers to impact some — or all — of these parts of your supply chain.

Removing Suppliers

Many supply chains have a producer of raw materials, a supplier that turns the raw materials into items, and a manufacturer that turns the items into products.

Additive manufacturing can take over the role of the supplier and manufacturer.

As long as you have the raw materials needed to make an item, you can use a 3D printer to create the perfect product. Any industry that requires an array of parts, such as aerospace, can take advantage of producing required parts on demand.

While the supplier of the parts is removed from the chain, industries don’t need to bring their entire process in-house. Outsourcing 3D printing to a third-party logistics (3PL) partner that implements additive manufacturing helps in three ways:

- Cutting the supplier, saving money

- 3D printing for bespoke parts made of nearly any material, for accuracy

- Outsourcing operations, for efficiency

[Related: How Outsourcing Your Supply Chain Can Save Your Online Retail Business]

Limiting Stock

Warehousing can be an expensive part of supply chains. The longer goods sit on the shelves of warehouses, the larger the cost becomes. For efficient supply chains, using the least possible warehouse space at any moment is key.

To keep inventory low, 3PLs utilize supply chain management software (SCMS) and other practices, such as just-in-time delivery.

Another way to reduce inventory is to only produce a good when you need it.

Additive manufacturing allows supply chains the flexibility to scale inventory at will. When a part or product is required, the order is sent to the 3D printer and produced on the spot.

Through additive manufacturing, businesses can reduce their reliance on warehouses.

Producing stock only when it’s needed is excellent for shipping, too. Currently, parts and products need to ship across the country — and sometimes the world — to reach their destination. 3D printing allows parts to be produced in any location with a printer, reducing the time and cost associated with shipping.

Generating Complete Products

Perhaps one of the most overlooked aspects of 3D printing is the ability to print incredibly complex systems, such as the entire cardiovascular system.

Eventually, 3D printing could remove stages, or even the entirety, of the assembly process, a step that businesses or their 3PL partners have attempted to make more efficient for years.

Before getting too excited about the possibilities, keep in mind that 3D printers can only print something with a blueprint. Each complex product will need a custom blueprint, as will each simple part you plan on producing. This process adds time and cost in the short term but could end up being a wise investment.

After learning about the potential of 3D printing for supply chains, you might wonder why more 3PLs aren’t investing heavily in the technology right now. However, downsides to 3D printing still exist.

Mass production remains a cheaper way to produce parts and goods, but only after a break-even point is met. For small quantities of items, 3D printing can be a more affordable option.

Granted, implementing 3D printing can be an expensive process, as businesses must:

- Purchase the 3D printer(s)

- Purchase the raw materials for printing

- Design blueprints

- Implement 3D printing into the supply chain

Quality is also a concern with 3D printing. While businesses can generate precise blueprints, 3D printers won’t always replicate the blueprint precisely, and the quality of the products could suffer because “an inherent weakness is literally built into the design” due to the top-down method of 3D printing.

With these downsides in mind, the time to apply 3D printers to your supply chain may not have arrived yet. Again, though, the technology behind additive manufacturing is continuing to improve, and these problems could someday be a thing of the past.

Depending on your current size and scale, additive manufacturing can either be a costly addition or a huge money saver. Currently, whether or not to implement 3D printing should be at each business’s and 3PL’s discretion. But the shift to 3D printing has already begun, and supply chain managers will need to follow suit at some point.

[Related: Successful Trends in Supply Chain Management]